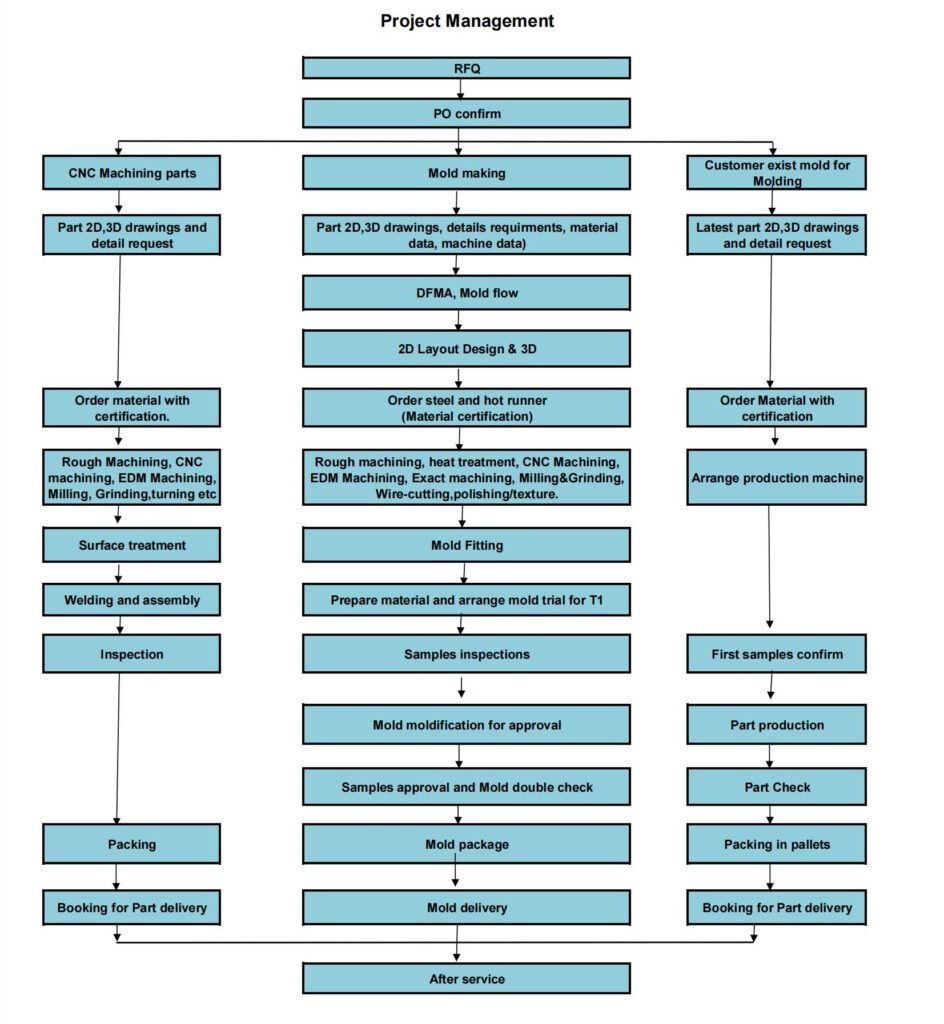

TTM specialized for precision machining, mold making and molding for over 10 years with strict project control management and weekly updating for project status to let customers know everything timely and clearly even thousands of miles from us.

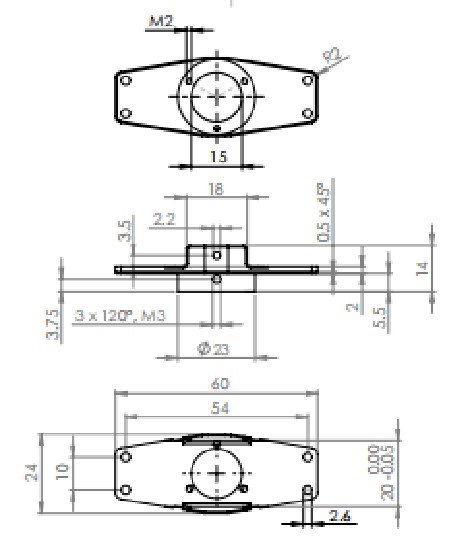

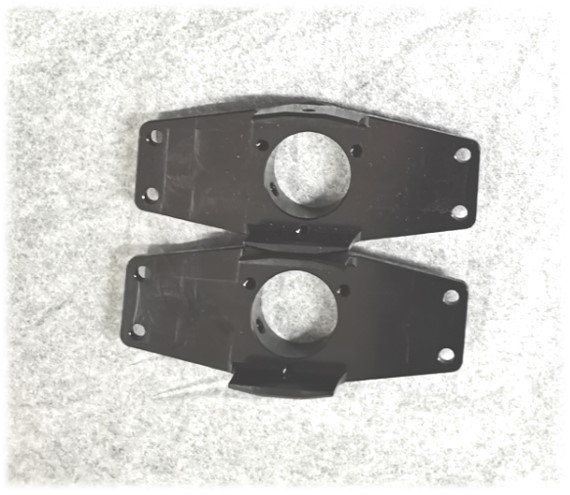

Precision Machining

Machining material

Plastic: ABS, POM(Acetal), PEEK, PET, Nylon6, PC, PE, PVC etc.

Steel: 1.1730, 1.2312, 1.2311, 1.2343, 1.2085, 1.2501, 1.1191 (C45), H13, S136, 738H, 718, P20, SDK61, 1.6582(EN24T), 1.2210(Silver steel), 1.0402(Mild steel), G04, etc.

Aluminum: ALU 6063, ALU 6061, ALU 6082, ALU 6060, ALU 6082(T6), ALU 6082-T651, ALU 7075 etc.

Stainless: SS303,SS304

Brass: Cooper, Bronze, Brass,

TTM Machining parts for industrial

automation, industrial, machinery, Aerospace, medic, fixtures, jigs, etc

TTM CNC machining project processing (6 steps) as below

1, Get order with 2D/3D drawing confirm.

2, Order material with material certification provides.

3, Weekly report of project status.

4, Surface treatment and assembly.

5, Final inspection and part pictures to customers.

6, Parts shipping after final checking.

Mold making and molding

Mold and Molding Project management with 6 steps

Mold design-Mold making-Mold trial and mold modification-Final inspection-Mold packing and shipping—Molding if requested.

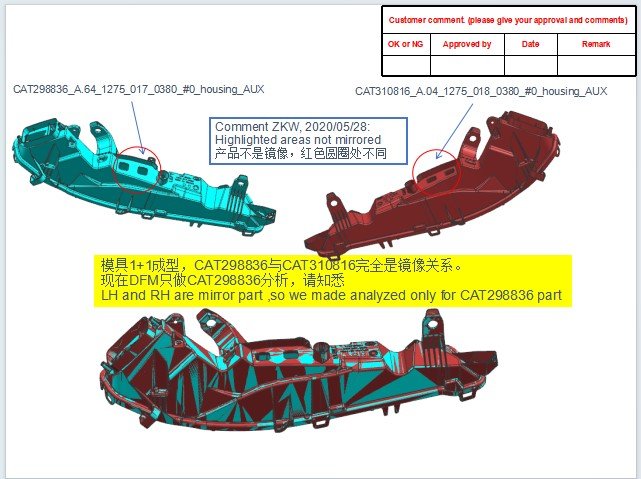

1, Mold design

After having order

*DFM (2-4 working days)

*Mold flow 2-4 working days)

*Mold 2D and 3D design 3-5 working days)

DFM and Mold flow

Document to customers: DFM, mold flow, Mold 3D/2D.

Weekly report

2, Mold making processing

- Weekly report with pictures for machining processing updating (from design status, material ordering status, mold machining status, etc)

We’ll prepare steel certification, heat treatment certification, and mold steel inspection reports during this step.

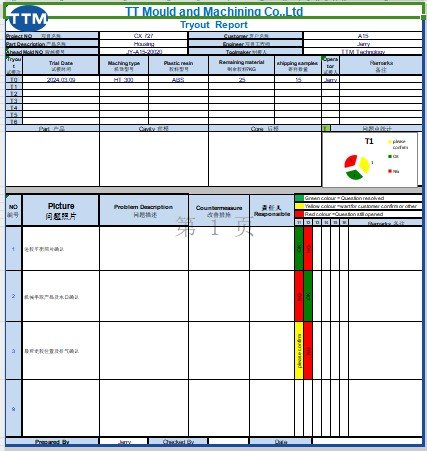

3, Mold trial and mold modification.

Each mold trial will come with a Trial report, inspection report, and injection parameter for customers). Injection parameter control is strictly to ensure stable conditions.

Mold modification or mold change till mold is approved (All mold trial and issues status will be in the mold trial report until all issues are closed to be green, Over 95% of our mold approved before T3)

Mold trial and mold modification

Checking list

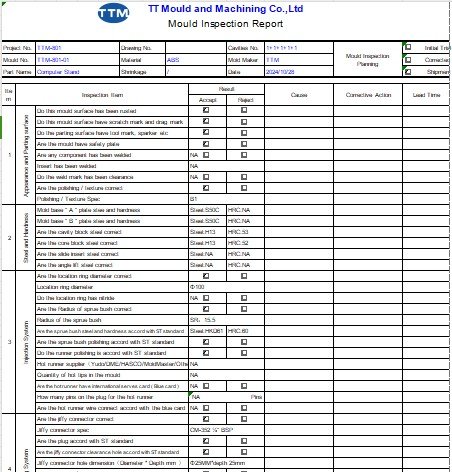

4, Final inspection before shipping

(checking list to check point to point)

After the final samples are approved for mold shipping.

We’ll disassemble all mold components and check all details refer customers, and approve mold 3D drawings to make sure all match for customer’s request. and clean the mold for shipping.

Tool delivery checking list printed into packing box with USB memories card attached mold 2D/3D, BOM, steel certification, heat treatment certification, steel inspection report, part inspection report, mold trial video, mold details pictures, etc in it.

Mold Packing

5, Mold packing and shipping

(Packing method will refer to shipping method by sea, air, or train)

Basically, air shipping will be with film or Vacuum packing.

Train or sea shipping will be with anti-rust firstly and vacuum outside before packing into a plywood carton box.

6, Molding

If mold stayed in China for production with China mold standards. We’ll arrange production after getting customer-approved samples.

During production processing, we’ll make SIP to customers and we have IPQC, FQC, OQC, and engineering departments to help manage all production processing for safety production.

We’ll provide an OQC inspection report, FAI inspection report, CPK, and material certification like ROHS, FDA, etc.

Molding